Delivering An Effective Solution for Wastewater Treatment in a Sensitive Environment

Our Client: Papagayo Beach Resort – Jan Thiel, Curaçao

More than a decade ago Papagayo opened an exclusive Resort with luxury villas on one of Curaçao’s finest locations: Jan Thiel Beach. Through the years Papagayo has expanded to become a major large international destination in the heart of the Caribbean with an upscale designed hotel on the beach, a trendy beach club and a versatile beach plaza, a casino, a contemporary spa, a wide range of restaurants and bars, a state-of-the-art fitness centre, a supermarket and various shops.

Being situated on an island brings with it some challenges when it comes to facilities management and dealing with wastewater is one of the most important considerations. Discharging effluent into the ocean can lead to critical and irreparable damage to corals and marine life, meaning it is essential to have an effective wastewater treatment plant.

The Challenge

The sewage plant at Jan Thiel & Papagayo Beach Resort Curaçao was outdated, with some serious operational problems, including several non-functioning components. As a consequence, the treatment process was failing to meet even the most basic standards for secondary water treatment at a site where the water needed to meet the highest standards. The situation was made worse by an influent flow which was higher than the capacity the plant could handle.

Solving the problems required some innovative solutions. The plant was located in a harsh environment where it was difficult to source specialist parts and components, so control systems needed to be simple, robust and based on equipment and technology with a proven track record of reliability.

Through every stage of the project the contractors building the new plant would also need to ensure that the plant would still operate effectively and provide a method for discharging sewage towards the existing wastewater plant to avoid any contamination of open water or nearby land. This required the installation of temporary pipelines, hoses and pumps.

Our Solution

To address the problems, the equipment needed to be replaced with a more appropriate, modern treatment system capable of handling large volumes of wastewater to produce a safe effluent for irrigation, while also eliminating excessive evaporation. Our modular Rotating Biological Contactor (RBC) solution, The BIOROTOR, was ideal for this project.

We designed a solution with three 60m3 primary tanks as primary treatment, and two lines of three BIOROTORs (6 BIOROTORs in total), as secondary treatment. It was installed across a 3,120m2 surface area. Additionally, we installed two lamella clarifiers after the BIOROTORs and added a subsequent chlorine disinfection as a tertiary effluent treatment.

The Results

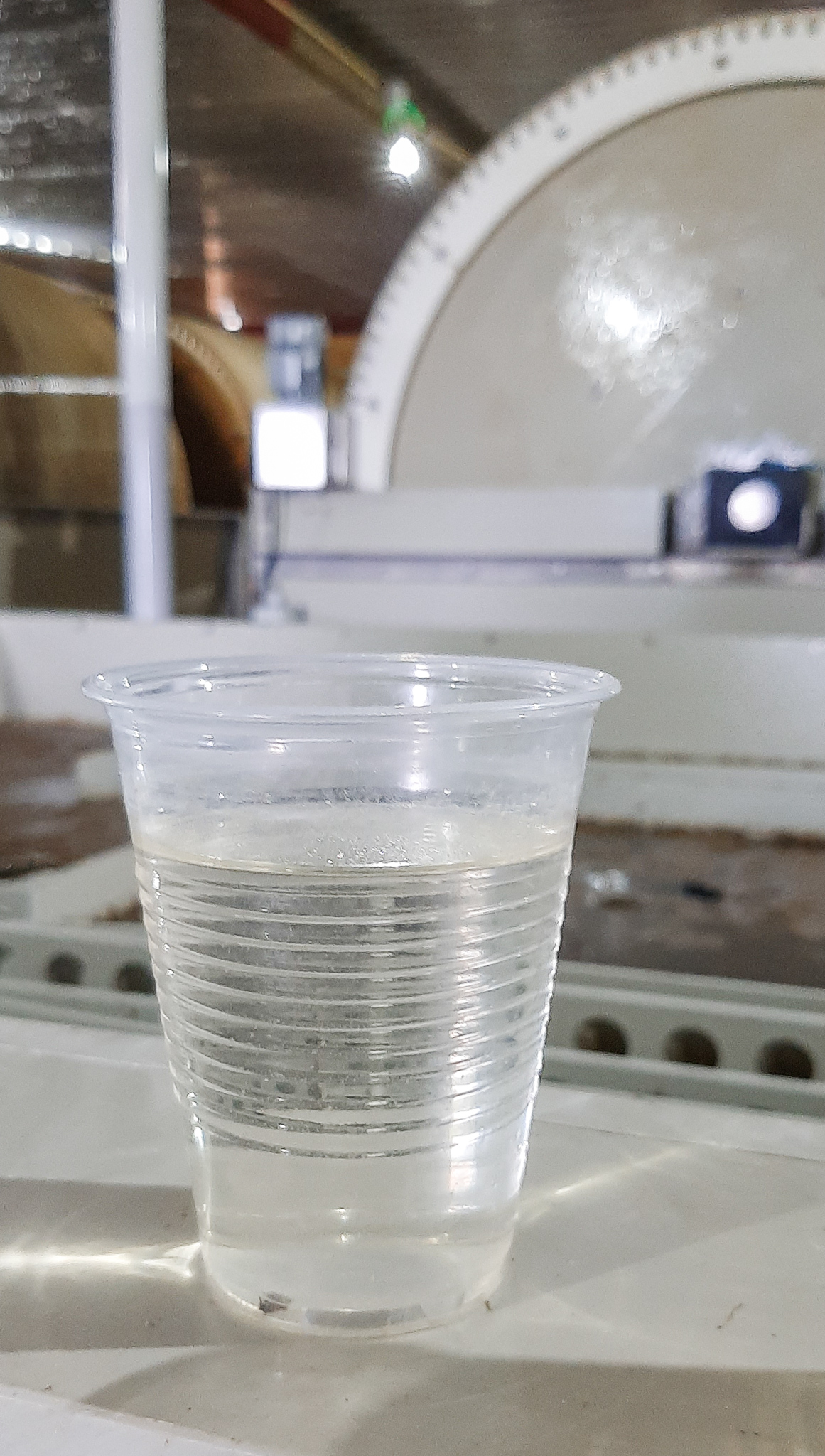

Installed quickly, the new WWTP at Papagayo Beach Resort Curaçao, has proved the perfect replacement for the old plant. With a peak flow of 5 m3 per second the new equipment is capable of purifying an average flow of 200 m3 of wastewater per day.

Most of this effluent is subsequently used for irrigation purposes, with most of the recycled water being used to keep the landscaping around the resort looking lush and healthy.

“This project was executed within the stipulated time frames and BIOROTOR technical team was extremely helpful and insightful on the overall design of the plant. The BIOROTORS are easy to install, have low maintenance and have proven to produce good quality of final effluent.

Being on an island and very close to the sea with its Coral Reefs, there are very strict standards for effluent quality being discharged. With the BIOROTORs we meet all the Governmental and Environmental requirements.

This is a great product for any off-grid sites that require a reliable wastewater treatment solution with high standards of final effluent quality.”

Paul Spiertz, Consultant & Managing Director – M.I.C. nv